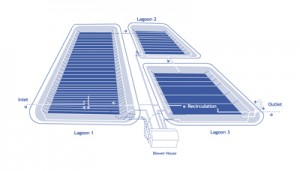

Serving the Southwestern states of Colorado, New Mexico, and Arizona, Aqua Sierra Inc.’s fine-bubble bottom laid wastewater technology leads the industry in its simplicity, cost savings, and efficiency. Our “Aerated – Facultative Lagoon” systems are backed by an unprecedented manufacturers 5 year guarantee to attain target BOD and TSS levels for domestic waste.

Imagine what these attributes could mean to your operation and bottom line:

- 1/6 the Energy Cost of Surface Aerator and 2-4 Times as Efficient

- No Sludge Removal for 20 Years

- No Odor

- Reduction or Elimination of Chemicals

- Only 1 Moving Part

- 30% Oxygen Transfer at 10’

- Free System Design

Energy Efficiency, Surface Area, & Fine Bubble Aeration

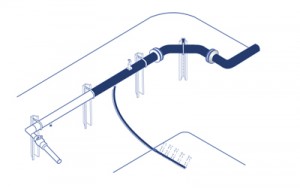

The difference between small and large bubble diameters is significant in wastewater treatment. Smaller bubbles take less energy to create while providing a much greater surface area for oxygen transfer to occur. Bubble diameter is directly related to horsepower and treatment due to the way air moves through water. Bubbles larger than 1/8” in diameter are limited in their mixing capabilities. Aqua Sierra Inc. (ASI) and Air Diffusion System’s (ADS) fine bubble aeration ranges in diameter from 1/8” to 1/64” providing the most efficient mixing and unsurpassed oxygenation.

The difference between small and large bubble diameters is significant in wastewater treatment. Smaller bubbles take less energy to create while providing a much greater surface area for oxygen transfer to occur. Bubble diameter is directly related to horsepower and treatment due to the way air moves through water. Bubbles larger than 1/8” in diameter are limited in their mixing capabilities. Aqua Sierra Inc. (ASI) and Air Diffusion System’s (ADS) fine bubble aeration ranges in diameter from 1/8” to 1/64” providing the most efficient mixing and unsurpassed oxygenation.

Independently Certified Using “ASCE” Oxygen Transfer Standards

Our aeration offers superior oxygen transfer to our competitors’ systems, and has been independently verified by former federal EPA advisor Michael Stenstrom in 2001. Three sets of tests were run according to the “ASCE” (American Society of Civil Engineers) standards for oxygen transfer. The results concluded that ASI & ADS’s fine bubble aeration delivers an industry best oxygen transfer rate of ~3% per foot of water (Standard Oxygen Transfer Efficiency). Click here to see the full mixing and oxygen transfer study.

Cost Effectiveness

At the end of the 20th year of operation, the single most expensive component is normally energy consumption. With the rising cost of energy, this issue has become even more important when assessing wastewater treatment options. By combining an efficient aerator with other advanced treatment technologies, aerated lagoons offer BOD, TSS, and nutrient removal rates meet all applicable permits year round. The internal digestion of sludge within our facultative lagoons increases the interval between dredging operations to 20 years on average. Furthermore, upon the implementation of our system, chemical use is greatly reduced, if not eliminated, creating greater cost savings.

At the end of the 20th year of operation, the single most expensive component is normally energy consumption. With the rising cost of energy, this issue has become even more important when assessing wastewater treatment options. By combining an efficient aerator with other advanced treatment technologies, aerated lagoons offer BOD, TSS, and nutrient removal rates meet all applicable permits year round. The internal digestion of sludge within our facultative lagoons increases the interval between dredging operations to 20 years on average. Furthermore, upon the implementation of our system, chemical use is greatly reduced, if not eliminated, creating greater cost savings.

A properly designed ASI/ADS system is 4-6 times more efficient than high-speed surface aeration, and 2-3 times more efficient than other diffusers. By using highly efficient compressors, operational costs are typically less than $0.01 per capita/day. The energy savings gained using an ASI/ADS system will quickly pay for itself.

Durability

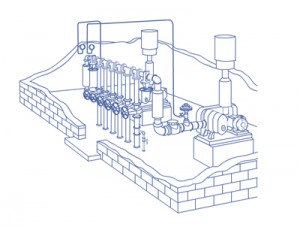

The only moving part of the ASI/ADS system is the air supply, making it one of the most reliable and easy to maintain systems on the market. Our tubing is UV resistant and modules are constructed Our polyethylene aeration tubing contains 1% carbon black to minimize degradation caused by harmful UV exposure and our disc module is constructed using 304 stainless steel maximizing and prolonging equipment life. All ADS equipment is guaranteed for 5 years against manufacturer defect.

The only moving part of the ASI/ADS system is the air supply, making it one of the most reliable and easy to maintain systems on the market. Our tubing is UV resistant and modules are constructed Our polyethylene aeration tubing contains 1% carbon black to minimize degradation caused by harmful UV exposure and our disc module is constructed using 304 stainless steel maximizing and prolonging equipment life. All ADS equipment is guaranteed for 5 years against manufacturer defect.

How to receive a Free System Design

Aqua Sierra Inc.’s wastewater treatment services are available to clients in Colorado, New Mexico, and Arizona. To receive a free facultative-aeration system design and cost estimate please fill out our wastewater worksheet. For the most accurate design and cost estimate, please include:

- A site plan: plan view (with contours if available), and side view (giving depth and freeboard)

- 1 year of monthly (average) inlet & outlet data

- A copy of the facility permit

- Information on the existing system: type, number of units, HP, and current price per kWh

We are confident that we can provide you with exceptional treatment and look forward to working with you!